Between the 11th and 13th of October, a team of 15 TI Fluid Systems representatives exhibited the company’s products, services, and innovations to our customers and the wider automotive industry at the International Suppliers Fair (IZB) 2022. Throughout the event, the company and our technologies were the subject of significant interest from our customers and fellow exhibitors, with our team involved in a series of constructive and promising business conversations. Of particular interest was the company’s Take The Turn strategy, which was showcased at the company’s booth.

The International Suppliers Fair (IZB) is Europe’s leading trade fair for the automotive supplier industry, and has become a major gathering for decision-makers over the years. Established in 2001, IZB is held every two years, with 2022’s event being the 11th time that the automotive supplier industry has flocked to Germany to exhibit.

The International Suppliers Fair (IZB) is Europe’s leading trade fair for the automotive supplier industry, and has become a major gathering for decision-makers over the years. Established in 2001, IZB is held every two years, with 2022’s event being the 11th time that the automotive supplier industry has flocked to Germany to exhibit.

IZB 2022 was a resounding success for the industry – 953 companies across 37 countries exhibited, and approximately 43,000 people visited the exhibition. The event comprised six halls that were all populated with exhibitors, including the e-mobility section within hall one, where we set up our 60m2 booth. Here, 15 TI experts from the company’s Engineering, Sales, Program Management, Product Management, and Business Development departments presented the company’s new generation technology, which focuses on electrification, and our Take The Turn strategy.

Across the event, our team hosted many of our customers at our booth. Numerous visitors mentioned that they were pleased to see that we have continued to focus on tank development and production, and others echoed this positive sentiment, noting that we are moving in the right direction.

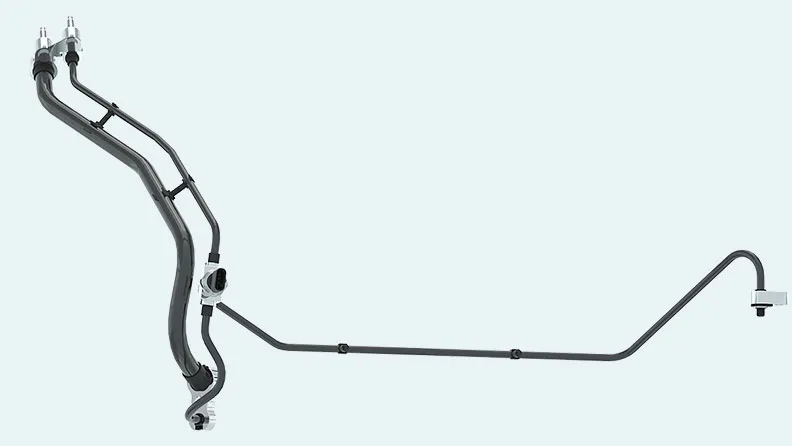

Our thermal product strategy was also very well received. The team at Volkswagen were extremely pleased that we exhibited our system competencies and modular concepts for battery electric vehicles, for example, while our vertical integration approach was praised by visitors to the booth.

Our ITMA 1.X, IBFD and ITMS solutions were particularly popular, with Volkswagen staff appreciating our concept of combining coolant and refrigerant in one module. Exhibiting at IZB also demonstrated to us as a team that some of our practices set us apart from our competitors. We were reminded that the blow moulding technology we implement for our coolant modules is a unique selling point, with others applying injection moulding practices instead.

The exhibition has fueled excitement for what comes next in our journey. We’re delighted that the show generated so much interest in visiting our E-Mobility Innovation Center in Rastatt, Germany, and we look forward to hosting interested parties at the facility. IZB reiterated that we are on the right track, and so our next steps will centre on customer delivery, ensuring that we maintain our ability to always service the needs of our customers.