Over the last 100 years, there have only been five automotive megatrends that have significantly affected our company. The first of these was fuel, the second was hydraulic braking, third was air conditioning, then came reduced emissions, and now there is electrification of the vehicle powertrain.

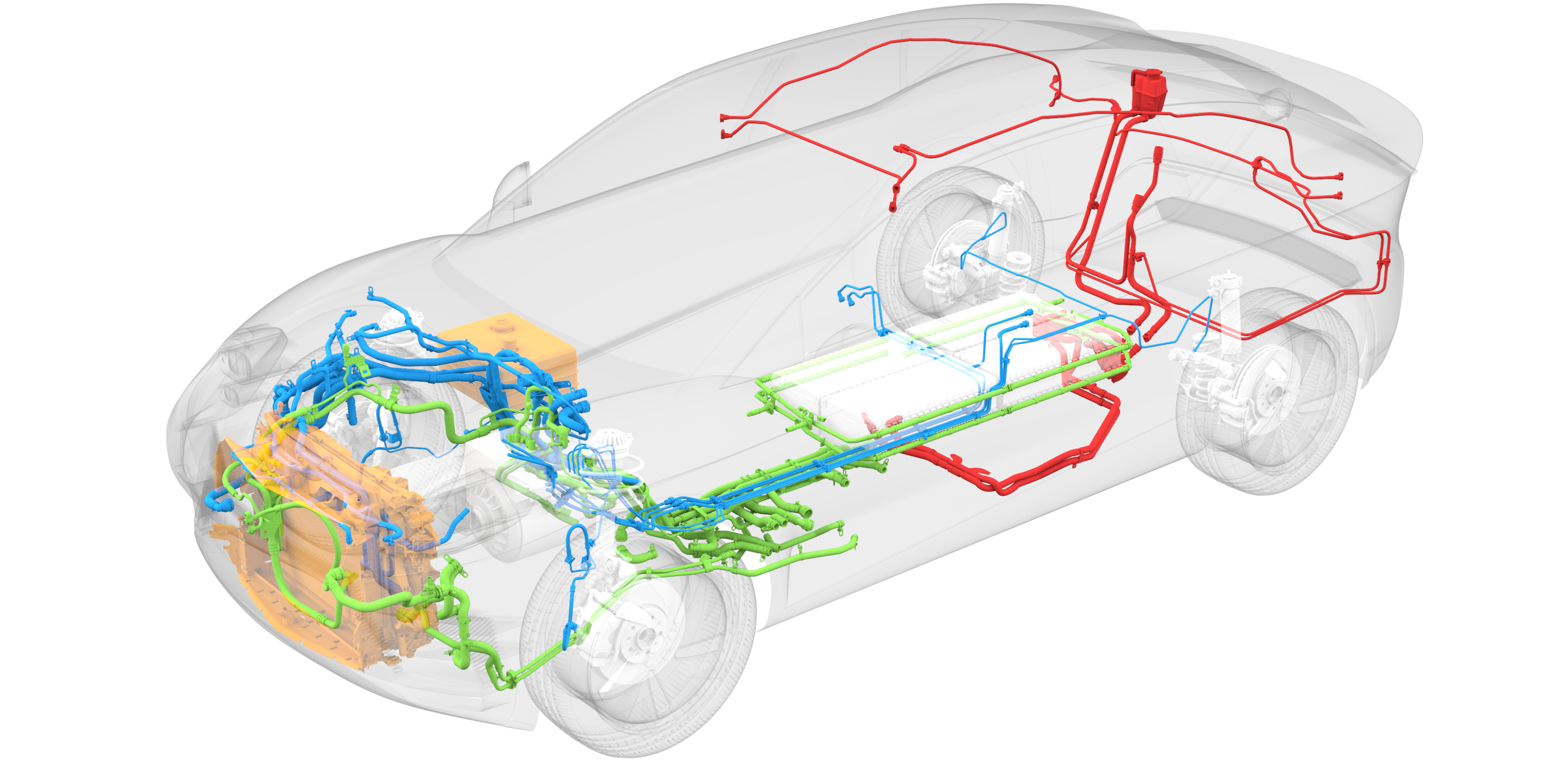

With electrification coming to the fore, thermal management systems are now in the spotlight. The fluids within vehicles are used to heat or cool the key components that electrify the vehicle – the electric motors, power electronics and the battery. Thermal management is needed to optimize the vehicle for peak performance. For example, a battery functions best when in a narrow temperature range which means that it must be heated or cooled to achieve maximum range and performance.

With electrification coming to the fore, thermal management systems are now in the spotlight. The fluids within vehicles are used to heat or cool the key components that electrify the vehicle – the electric motors, power electronics and the battery. Thermal management is needed to optimize the vehicle for peak performance. For example, a battery functions best when in a narrow temperature range which means that it must be heated or cooled to achieve maximum range and performance.

We’ve been able to adapt our fluid carrying products and our manufacturing assets to meet the thermal management requirements of electric vehicles. Our HVAC team – now known as Thermal – reacted to the shift to electrification and the opportunities that could come with it long ago, even when gasoline and diesel powertrains were still on the industry’s front burner.

Working closely with our global OEM customers as well as numerous battery manufacturers, we were able to understand where the world’s automotive market was heading. The message was consistent: electrification is going to be the future. Fortunately for us, this was a shift that we could really take advantage of through our product portfolio.

The hybrid electric and battery electric work that we have undertaken over the past several years has all stemmed from the early initiative of our HVAC team. The automotive industry’s journey towards electrification has started and is now accelerating. That’s why we are committing more knowledge and resources to our growing electric vehicle product portfolio. While the market for vehicles powered by internal combustion engines will shrink over time, it will not disappear overnight. So, we will continue to support our customers with market leading gasoline and diesel products as the industry shifts to electric vehicles.

As revolutionary as our SIB technology was, the 10-inch plastic parison opening that was required meant that it was limited on some applications. So, towards the end of 2013, we showed off our adaptable plastic fuel tank advanced process technology (TAPT) at the tank.tech conference in Munich. The TAPT technology used existing blow molding to separate a pre-formed, blow-molded parison into two halves while a robot inserted the fuel system components into designated areas of the tank assembly. TAPT could operate without size or location limitations.

As revolutionary as our SIB technology was, the 10-inch plastic parison opening that was required meant that it was limited on some applications. So, towards the end of 2013, we showed off our adaptable plastic fuel tank advanced process technology (TAPT) at the tank.tech conference in Munich. The TAPT technology used existing blow molding to separate a pre-formed, blow-molded parison into two halves while a robot inserted the fuel system components into designated areas of the tank assembly. TAPT could operate without size or location limitations.