Join TI Fluid Systems at the SAE Thermal Management Systems Symposium.

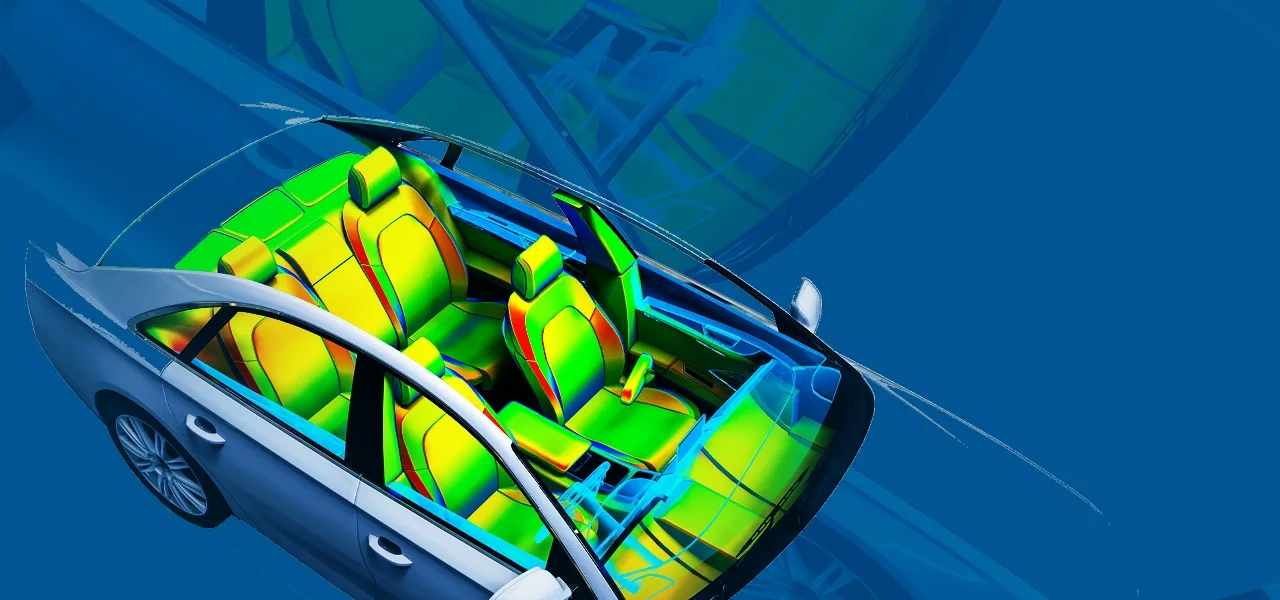

Electric vehicles bring a host of new challenges to the industry: how to keep things cool around a hot battery; how to conserve energy and reduce engine emissions; how to improve the cabin environment; and how to meet global standards and regulations. This year’s Thermal Management Systems Symposium (TMSS) will bring the industry together to tackle these important questions and much more.

In two productive days, you’ll get up to speed on regulations, technology and industry trends, and interact with engineers who do what you do. This is where important conversations happen. Don’t miss this vital opportunity to interact with and network the best of the best in the field of ground vehicle thermal systems technology and thermal systems management.

————

When

October 2-3, 2024, All day

Where

Saint John’s Resort

44045 Five Mile Road

Plymouth, MI 48170

Click here to register for the event!