- TI Fluid Systems will open new e-Mobility Innovation Centers (eMICs) in Nagoya, Japan and Incheon, South Korea this summer

- eMICs promote collaboration between the company and its customers to efficiently develop thermal management solutions for electric vehicles

- The new facilities will follow the successful eMIC blueprint laid out in Rastatt, Germany

AUBURN HILLS, MICHIGAN, USA (6 June 2023) — TI Fluid Systems (TIFS), a leading global supplier of automotive fluid systems technology, will open two new e-Mobility Innovation Centers (eMICs) in Japan and South Korea this summer.

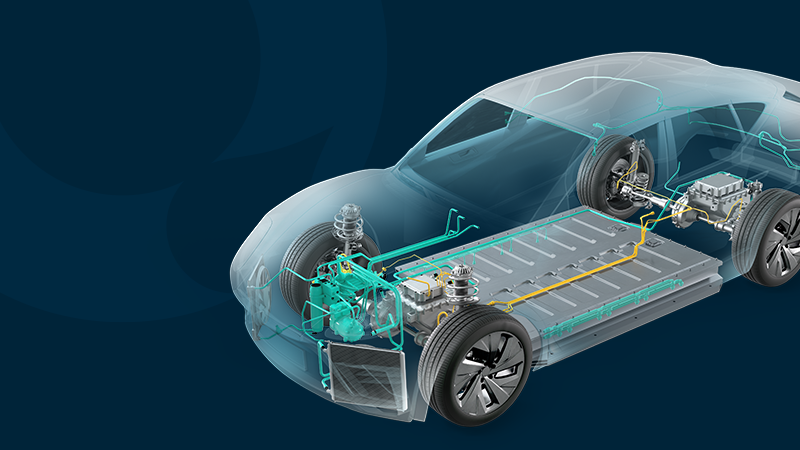

The new centres, located in Nagoya, Japan and Incheon, South Korea, will fast-track the development of thermal management solutions for electric vehicles (EVs) in Asia, and allow TI Fluid Systems to work more closely with its customers in the region.

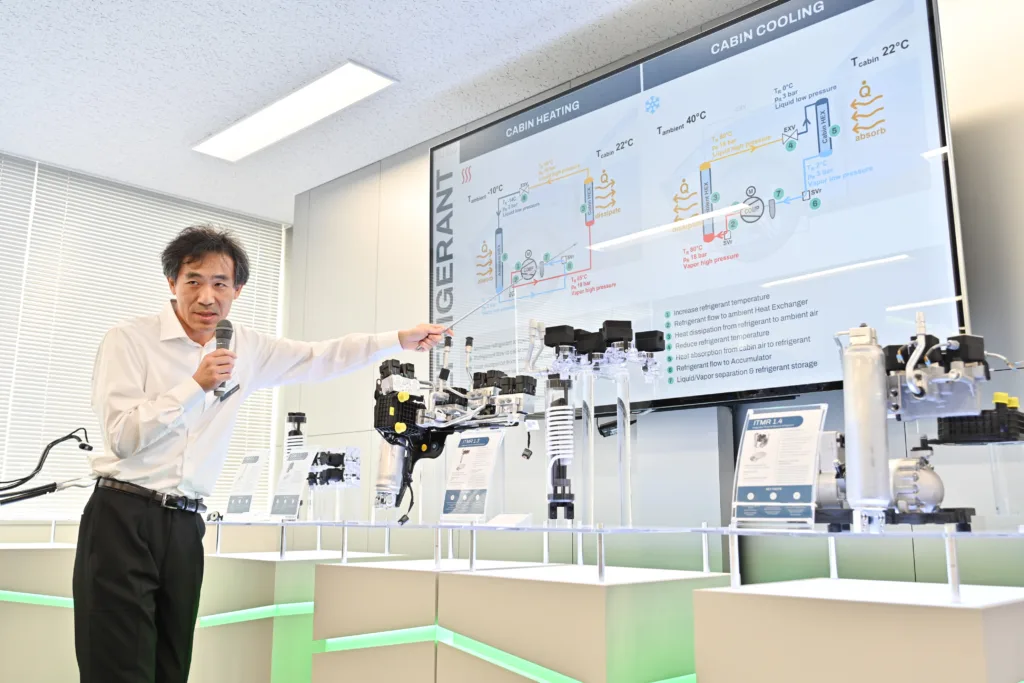

Following TI Fluid Systems’ first eMIC, which opened in Rastatt, Germany last year, the new facilities bring together six core competencies: virtual engineering, designing, processing, prototyping, product testing, and vehicle testing. This empowers engineers in the region to design, develop, simulate and visualize thermal management solutions at vehicle, module and component level. Unique to TI Fluid Systems, this enables it to introduce class-leading technology to market much faster than before.

TI Fluid Systems’ new Japan eMIC is strategically located in Nagoya, in close proximity to its customers’ technical centres and the Shinkansen high-speed railway. Set across 1,900m2, the eMIC features a state-of-the-art virtual reality system, 3D printing capabilities and an impressive high-resolution digitalised visualisation.

Strategically located in Incheon, in close proximity to its customers’ technical centers and the international airport, TI Fluid Systems’ new South Korean eMIC is perfectly placed to serve the nation’s automakers. It also features a state-of-the-art virtual reality system, 3D printing capabilities, as well as product and vehicle testing capabilities. Underlining TI Fluid Systems’ commitment to electrification, the South Korean eMIC also features multiple recharging stations.

The opening of the centres in Japan and South Korea continues TI Fluid Systems’ plan to build a global network of eMICs, with further facilities in the Asia Pacific and North America regions set to be announced later this year.

Hans Dieltjens, President and CEO of TI Fluid Systems, said, “The opening of these new facilities in South Korea and Japan represents an important milestone in the development of our e-Mobility Innovation Center network. Vehicle manufacturers in these markets are playing a leading role in defining the next generation of EVs globally. Working more collaboratively to tackle the thermal management challenges they face will have a profound impact on manufacturers’ development rate and vehicle performance.”

To find out more about TI Fluid Systems, visit www.tifluidsystems.com.

About TI Fluid Systems

TI Fluid Systems is a global innovator of thermal and fluid system solutions for the full range of current and developing vehicle architectures. Serving all major automotive manufacturers, with more than 100 years of automotive supply experience; TI Fluid Systems operates across 28 countries with a commitment to improving efficiency, performance and sustainability worldwide.

In Poland, two female students, Monika Swieciochowska and Klaudia Piwowarczy, were recently awarded two-year scholarships at the Adam Mickiewicz University in Poznan, while Zuzanna Szczelina and Kinga Mycek have been selected at AGH University of Science and Technology in Krakow. All four of these students were chosen by their universities on account of their outstanding academic performance.

In Poland, two female students, Monika Swieciochowska and Klaudia Piwowarczy, were recently awarded two-year scholarships at the Adam Mickiewicz University in Poznan, while Zuzanna Szczelina and Kinga Mycek have been selected at AGH University of Science and Technology in Krakow. All four of these students were chosen by their universities on account of their outstanding academic performance.